Lenticular Lens/Software

- 2012-07-13 11:07:38

-

According to the visual effect, 3D printing can be divided into three types: (1) 3D image: scenery and objects in the image are separated, with three-dimensional effect. Former things be vividly portrayed, intermediate level is transitional are distinct, and the background has a certain sense of depth.(2) amination: according to the creative design, the objects in the image have a continuous transformation, forming special animation effects, which are the extension of variable image effects.(3) variable image: you can get different graph effects from different perspectives.

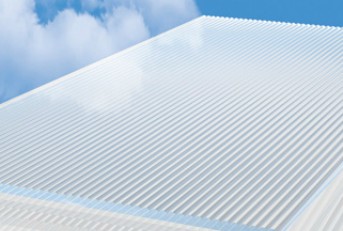

From material, it is mainly divided into three kinds, namely classification of 3D printing substrate. At present, on the market,these three kinds of lemnticular lens sheets are mainly adopted,such as polystyrene (PET), polypropylene (PP) and polyvinyl chloride (PVC). 1 polystyrene resin (PET) polystyrene resin (PET) are used to make hard plastic lenticular lens, with use of common printing ink directly. Polystyrene resin material can shape concave-convex cylinder-shaped grating film after injection molding process. Column Styrene resin has a good stability, high quality and raw materials are non-toxic with high chemical-resistance, but it is more difficult for glue processing. It is often used for toys, fine advertisement, etc. (2)Polypropylene (PP) polypropylene (PP) can be used for common ink immediate printing, but the surface needs sparks to deal with, and its ink drying speed is faster than PET.PET texture is softer than PET, harder than PVC. Stability is higher, but the quality of images is common. Raw material is non-toxic with low chemical resistance. It is much easier for glue processing, often used for packaging, stationery, etc. (3) Polyvinyl chloride (PVC) polyvinyl chloride (PVC) is used to make soft plastic cylindrical lens lenticular lens board. To use hot hydraulic press to press pictures and PVC into the shape through a metal lenticular lens roller or grating sheet. PVC stability is low, and the picture quality is rough. In addition, because the PVC lenticular lens is toxic, not friend to environment, and normally not used for toys and food packaging products.

-------------------------------------------------------------------------------------------------------

Hot tags:

3d lenticular printing service3d lenticular designlenticular print3d lenticular cup3d lenticular printing3d lenticular poster3d lenticular picture3d lenticular sheet3d lenticular notebook3d lenticular bookmark3d lenticular software3d lenticular card3d lenticular postcard3d lenticular placematlenticular plasticlenticular sheetLenticular Lenticular lens Lenticular sheet Lenticular printing 3d Lenticular Lenticular Lenticular image 3d printing 3d print 3d printer Lenticular Exporters Lenticular manufacturers Lenticular factory lenticular Suppliers Lenticular array lenticular Importers 3d lenticular 3d lenticular printing service 3d lenticular design lenticular print 3d lenticular cup 3d lenticular printing 3d lenticular poster 3d lenticular picture 3d lenticular sheet 3d lenticular notebook 3d lenticular bookmark 3d lenticular software 3d lenticular card 3d lenticular postcard 3d lenticular placemat lenticular plastic lenticular sheet lenticular plate lenticular board lenticulars 3d lens 3d sheet fly-eye-lens

- Previous [Return Home] [Print] [Go Back] Next

News

Products Search

Contact Us

Contact Person:

Ms.ElaineTel:

0086-13136538608Fax:

E-mail:

sales@ppoo.com-